Product Overview

Ready to wear meets designer quality

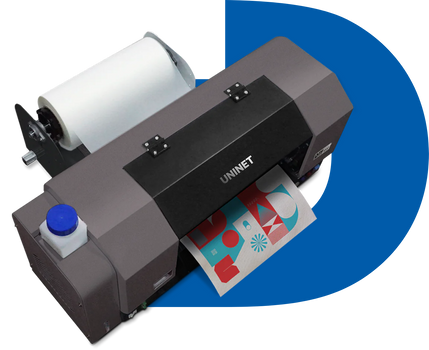

The UNINET DTF 1000 is an ink-based direct-to-film digital transfer printing system with a roll feeder capable of printing up to A3+ or 13 inches wide. It is built to perform for the short-volume production of exceptional quality and full-color print transfers for the digital apparel decorating market, which can be applied to light and dark-colored garments.

Good things come in smaller packages.

This 13" print width, desktop-sized DTF printing equipment is compact yet powerful, expertly configured for manual DTF powder application, and capable of producing simple or intricate, colorful weedless digital transfers in a single pass. As an optional upgrade, the DTF™ 1000 can be paired with the* UNINET® DTF™ 1000 Auto-Powder Unit to enable fully automated powder application, curing, and drying for a comprehensive printing solution, transforming it into the most cost-effective DTF printing device on the market. (* UNINET® DTF™ 1000 Auto-Powder Unit is sold separately).

From apparel decoration to fashion statement in the blink of an eye.

Envision having a print shop on your desktop to create fashionable custom-made apparel, accessories, home décor, and more, using your designs to produce digital transfers that are stretchable, durable, soft-hand, and vibrant in color. Easily print full color and white graphics for application to virtually any textile.

The UNINET® DTF™ 1000 is built to make a statement for your business from day one.

In Addition, the printing system features

- Printer Roll Feeder with auto-feeding capabilities

- Ink tanks with Continuous Feed System

- Bluetooth Humidity and Temperature Sensor

- Internal Controllable Vacuum Suction (prevents film buckling)

- White Ink Circulation Engine (helps circulate white ink)

- UNINET® DTF™ 1000 Auto Powder Unit, as an optional upgrade, can be paired to the DTF™ 1000 transfer printer to enable fully automated powder application, curing, and drying for a comprehensive printing solution. (Optional upgrade is sold separately)

BEYOND THIS, UNINET PROVIDES

- UNINET DTF Cleaning Solutions

- UNINET DTF Inks

- UNINET DTF Transfer Film Papers

- UNINET DTF Powders

- USA Training and Technical Support*

- UNINET DTF USA Warranty

|

Specifications |

|

|---|---|

| Printhead | A high-definition, professional piezo inkjet printhead |

| Maximum Resolution | 5760 x 1440 dpi |

| Ink Type | CMYK+ White with bulk ink system |

| Cartridge | 500ml bottles |

| Print Speed | 6 to 8 minutes A3 Sheet |

| Media Capacity | 328 ft (100m) PET film roll: 13 in (33 cm) |

| Maximum Media Width | 13 " (330mm) |

| Interface | USB |

| Rated Current | 5A |

| Rated Power | 500W |

| Dimensions | 28"W x 23"D x 13" H (711 x 584 x 330mm) |

| Shipping Dimensions | 36" X 15.5" X 13.5" (914 X 394 X 313mm) |

| Weight | 48lbs (21.8kg) |

| Shipping Weight | 60 lbs (27.2kg)* |

| Bundled Software | UNINET DTF ProRIP |

| Compatible OS | Windows® 10 & Windows® 11 |

| Warranty | USA Warranty, parts & labor |

| Included with Printer | CMYK+W Bulk Ink system, DTF 13" x 328ft roll of transfer film, DTF white adhesive powder, maintenance solutions and accessories Certificate for DTF Master Class Video Training. |